Galvanized steel and aluminum have similar properties in that they are both anti-corrosive. However, some applications are more suited for aluminum, and some prefer galvanized steel. Aluminum is a metal which is naturally anti-corrosive. This means nothing needs to be added to the aluminum in order for it to withstand rust and weathering. Galvanized steel is steel which goes through a chemical process in order for it to become resistant to rust and weathering. The steel itself does not have anti-corrosive properties, so it must be bonded with zinc to prevent corrosion. Here are some areas where aluminum beats out galvanized steel and vice versa.

Aluminum Over Galvanized Steel. In addition to being naturally anti-corrosive, aluminum also has natural antibacterial properties. Aluminum has a hard, smooth surface where galvanized steel is rough and porous and can hold and accumulate bacterial growth. This makes aluminum more suitable than any other metal when it comes to medical equipment.

Aluminum is also a lower density than galvanized steel, so it has a higher heat exchange and better cooling and defrosting properties. So in the case of food storage, aluminum’s ability to cool more efficiently and resist corrosion makes it more suitable.

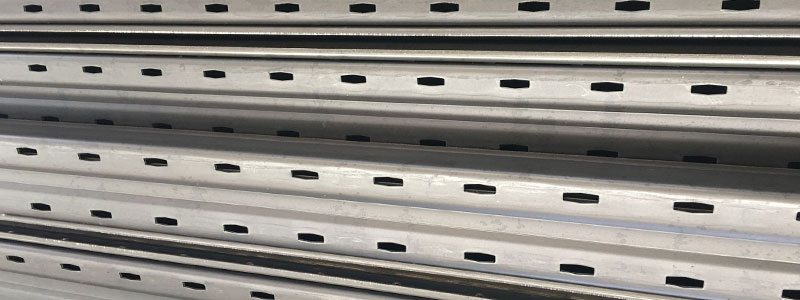

Galvanized Steel Over Aluminum. As stated before, galvanized steel has a higher density than aluminum. This makes it more suitable for supporting heavier structures like bridges and buildings. Aluminum does not have the strength and density to perform heave jobs such as this. While regular steel can be used in these instances, galvanized steel needs little to no upkeep in order for it to retain its anticorrosive properties.

Galvanized steel is also better suited for industrial applications where caustic soda and potassium hydroxide are involved. Due to its zinc film, galvanized steel is resistant to these mild alkaline solutions more than aluminum would be.